Morn Laser

WhatsApp +86 151 6916 6350

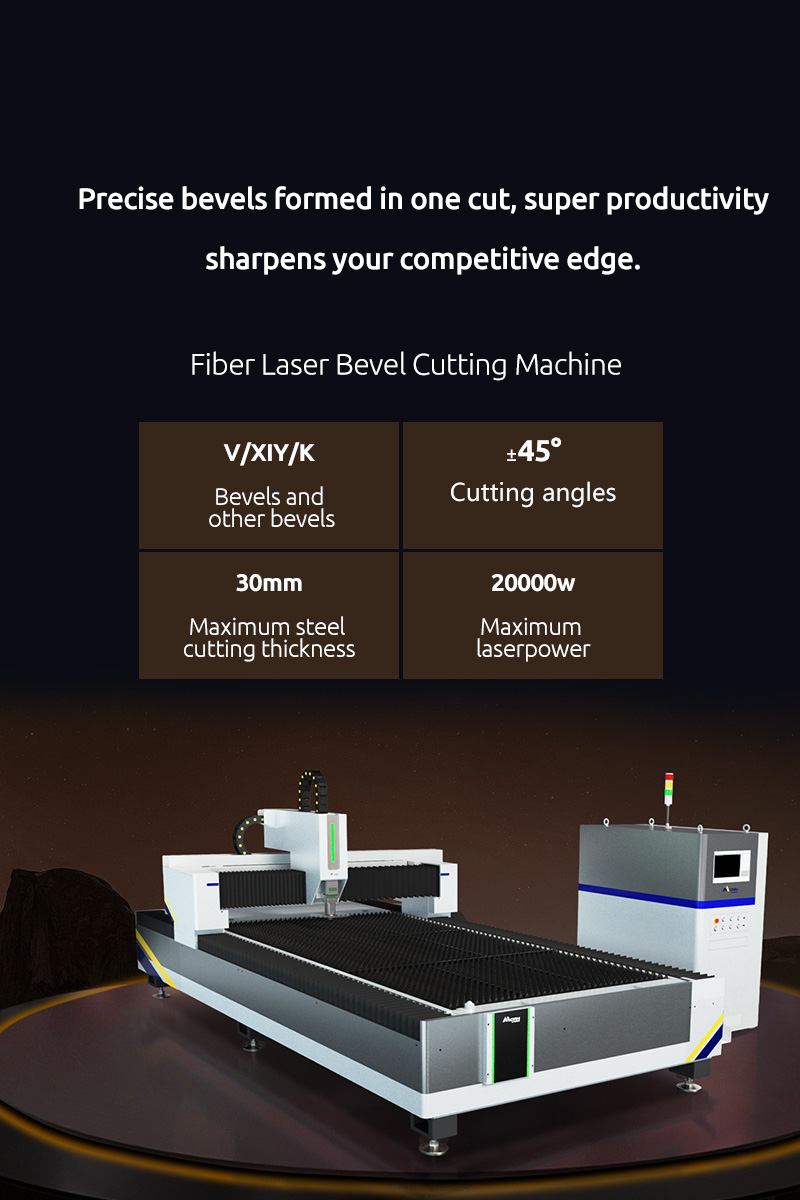

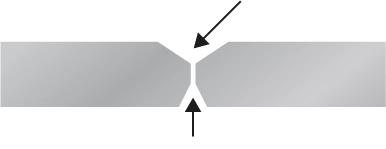

Ultra-high bevel cutting efficiency with fewer procedures

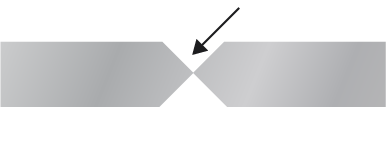

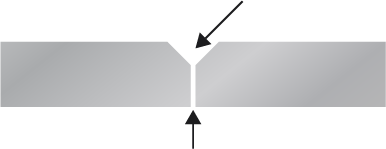

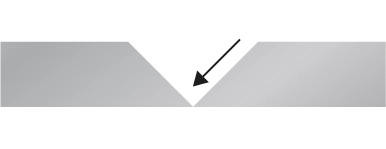

Form your bevel in one shot within ±45°. The produced cut-offs are ideal for zero gap welding. No extra cutting and subsequent grinding will be needed, so that you benefit from a 75% efficiency boost than traditional metal cutters.

Thanks to a three-dimensional five-axis control system, Morn Laser’s high-power cutting head precisely controls bevel cutting angles and cuts bevels in convincing quality. The finished workpiece fits better for seamless welding compared to the traditional processes ever since.

You will benefit from oblique perforation, post-perforation precise positioning, and improved cutting efficiency.

You could freely choose a variety of corner transition methods, such as corner one-cut and multi-cuts.

Two sets of intelligent sensors are equipped for easy monitoring real-time gas pressure and contamination of the protective lens.

From control to cutting, a closed-loop system allows higher operation timeliness, greatly enhancing bevel cutting efficiency.

The vision calibration device ensures model parameters to be highly accurate and easy to obtain, saving cost on maintenance.

A specially designed algorithm is used to ensure consistent bevel cutting size in case of different angles and nozzles, allowing you to cut bevels more conveniently, no need to compensate for each mechanical change.

Plane perpendicularity compensation brings high accuracy bevel cutting even if the plate is not horizontal.

Consistent quality assurance proved by practice

Time-sharing, partitioning and segmented dust extraction structure instantly removes the smoke and dust during cutting.

Re-cutting becomes so easy

Thanks to the Japanese original imported servo motor with a built-in absolute encoder, you can resume cutting from any perforation point or select the previous or next perforation point to continue cutting according to the position of the break-point. No more worries of power failure.

“ I just bought one metal laser bevel cutter from Morn Laser. We have been very satisfied and pleasantly surprised with the machine quality and performance. If you’re looking for a good laser cutter with good value, look no further. We highly recommend Morn Laser. ”

Free your hands with auto focus laser head and speed up sheet feeding with dual pallets, which greatly reducing standby time and enhancing work efficiency.

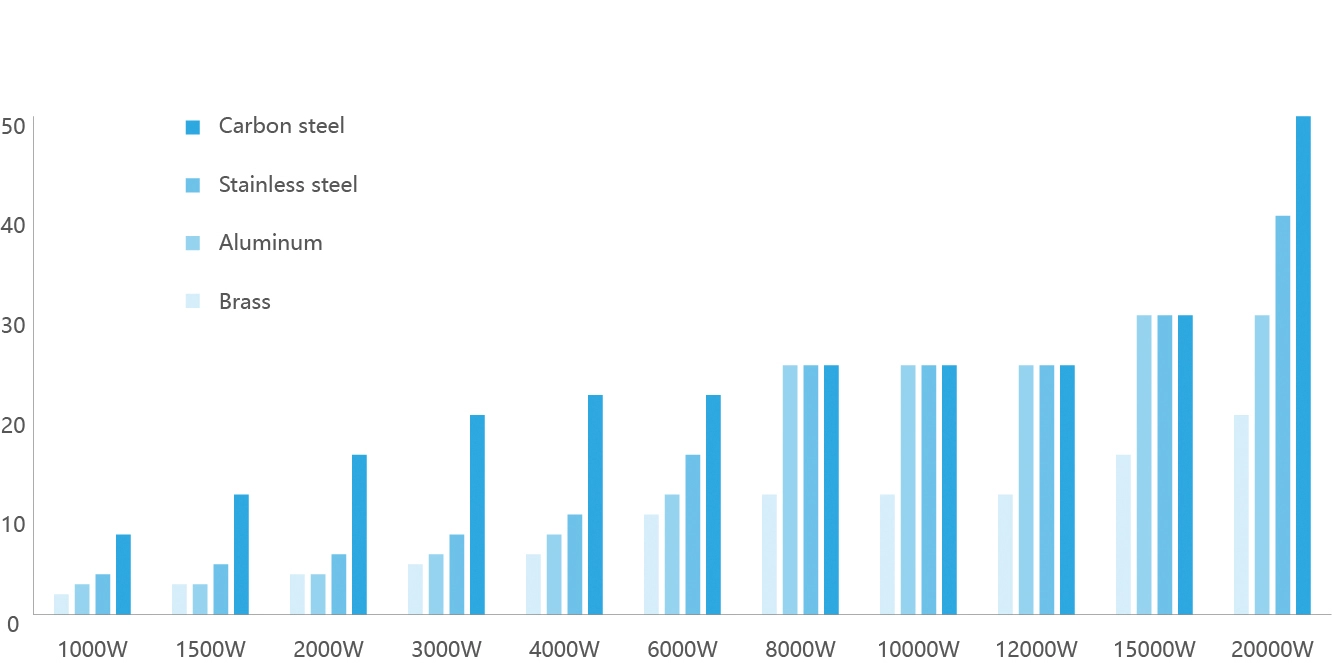

You will impress with top-notch laser cutting performance over the entire sheet thickness range, and double your production efficiency thanks to the auto loading system and dual pallet exchanger. Also a variety of intelligent functions and full cover provide you a safe and clean working environment.

Rather than being a like-for-like upgrading product, this metal bevel cutter breaks the limits of the straight cutting section and makes various bevel cuts on metals just in one step.

| Model | MT-L1530F | MT-L2040F | MT-L2560F |

| Working Area (Customizable) | 3000*1500mm | 4000*2000mm | 6000*2500mm |

| Laser Power | 2000W/3000W/4000W/6000W/8000W/10000W/12000W/20000W/30000W | ||

| Bevel Angle | ±45° (Expandable) | ||

| X/Y Axis RepeatedPositioning Accuracy | ±0.02mm | ||

| Maximum Idle Speed | 120m/min | ||

| Maximum Acceleration | 1G | ||

| Laser Power | AC380V 50HZ AC220V 60HZ | ||

Мы рады, что вы предпочли связаться с нами. Пожалуйста, заполните нашу короткую форму, и один из наших дружелюбных членов команды свяжется с вами.