Morn Laser

WhatsApp +86 151 6916 6350

Reduce material waste to the minimum

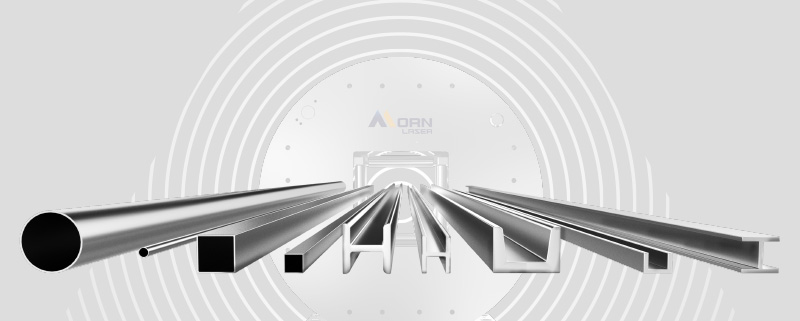

Efficient clamping leads to productive tube cutting

virtue of the automatic adaptations to the diameters of your tubes. Thanks to the adaptive clamping system, you benefit from cutting of round tubes, square tubes, rectangular tubes, U-shaped tubes, channel steels, I-beams, special sections, and open profiles with enhanced efficiency.

Efficient clamping leads to productive tube cutting

virtue of the automatic adaptations to the diameters of your tubes. Thanks to the adaptive clamping system, you benefit from cutting of round tubes, square tubes, rectangular tubes, U-shaped tubes, channel steels, I-beams, special sections, and open profiles with enhanced efficiency.

Make full use of versatile contouring options

Cut every conceivable contour with this laser tube cutter, your design options are tremendous.

Get more out of your mass production

The fully automatic loading system lifts, intelligently sorts, and instantly feeds the whole bundle of tubes. Single tube loading takes only 15s.

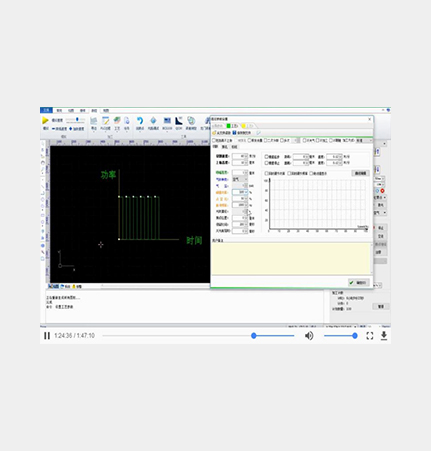

User-friendly interface simplifies your operation

Support nesting of parts of various shapes all at once with minimum waste

Reduce cutting times and minimize waste in production.

Integrate drawing functions of extrude, cut, hole and V-groove etc., even user with zero CAD experience can get start easily

View real processing with no production interruption

Special safety-glass and sealed cutting areas provide a safe view of the processing area during operation, while an independent safety system allows you to load a new tube section with no production interrupting.

“Our productivity has increased by 30 percent due to the new laser tube cutting machine. It allows us to reduce costly secondary manufacturing processes. Some old systems have even been made obsolete.”

Roman

Production manager

Alvin

Long and heavy tube cutting expert, truly zero-tailing. Make full use of your tube with this four-chuck tube laser cutting machine. Automatic bundle loader brings efficient production of big lots.

Change instantly from sheet to tube without the need for additional setup or tooling. Use your time making products instead of making changeovers. It’s the ideal way to maximizeyour return on investment.

Rather than being a like-for-like upgrading product, this metal bevel cutter breaks the limits of the straight cutting section and makes various bevel cuts on metals just in one step.

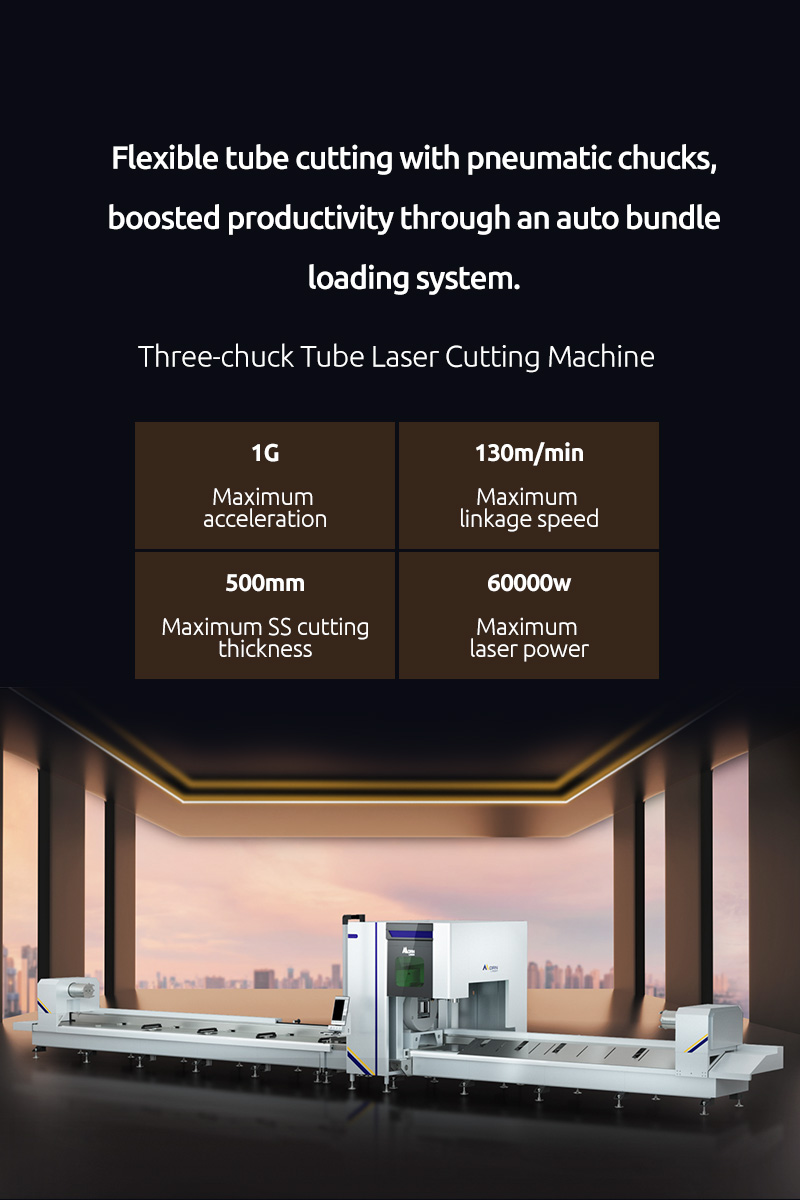

| Model | MT-6000 |

| Pipe Diameter | φ20mm-160mm/ 200mm/350mm/500mm |

| Pipe Length | 3m-15m |

| Laser Power | 1000W/1500W/2000W/3000W/4000W/6000W/12000W |

| Max. Idle Speed | 80m/min |

| Pipe Length | 3-15m |

| Max. Acceleration Speed | 1 G |

Мы рады, что вы предпочли связаться с нами. Пожалуйста, заполните нашу короткую форму, и один из наших дружелюбных членов команды свяжется с вами.